Why You Need Clean Compressed Air

Clean air in your compressed air system is essential for the safe and efficient operation of this reliable power source. Harmful contaminants like oil, dust, dirt, rust, and water-alone or in combination-can attack your system and:

- Clog sensitive pneumatic instruments.

- Reduce the efficiency of air-operated tools.

- Wear out seals and erode system components.

- Increase maintenance and repair costs.

- Contribute to product rejects, production downtime-even complete plant shutdown.

Raising the quality of compressed air

To keep the compressed air system clean and enhance the compressed air quality, a combined set of high-quality, high-performance filter and drain valve are used. Compacted filters are used to remove water, grease, and foreign substance in the compressed air, however, compressed water molecules are too tiny to be prevented from penetrating through the filter. Furthermore, even though the larger particle such as grease, rust particle, and foreign substance are blocked and attached to the filter, eventually it will clog the filter, and results in a larger pressure reduction to the compressed air, further increase the maintenance cost to replace the filter.

How does TONAIR compressed air separation filter work?

TONAIR compressed air separation filter with an innovative designed structure remove the water and unclog the filter effectively by applying multiple application of physical principles such as the flow disturbance separation. Most of the water and foreign substances can be removed, and its filter will not clog easily thus extend its life span. It will not cause pressure reduction, and the compressed air system can be operated smoothly and at ease.

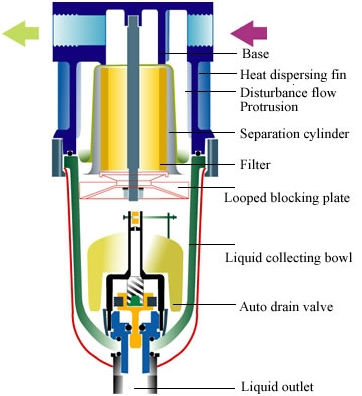

TONAIR compressed air separation filtering procedure

The compressed air enters into the interior through the inlet, and collides with the circular base to create a rotary airflow. Since the periphery of the filter has heat-dispersing fins and the interior has disturbance flow-protruding members to lower the temperature and the flow rate of the compressed air, the airflow will passes through the rotary flow separating the cylinder of covered filter, such that the water and dirt will not contact the filter directly, and quickly be separated and be collected at the bottom. To prevent the water from being spilt onto the filter, a looped-blocking plate is installed to re-direct the water and foreign substances to the liquid collecting bowl at the bottom as they are discharged in fixed quantity by the AD-34 automatic drain valve. After the compressed air passes through a multiple layer of disturbance flow separation for the removal of water and foreign substances, it will flow upward toward the rotary blocking plate and pass the metal annealing filter, and finally the pure and high-quality compressed air will enter into the pipeline from the outlet.

SPECIFICATIONS

| Model | AF-104A | AF-104B | AF-106A | AF-106B |

| Connection Size | 1/2" PT (NPT) | 3/4" PT (NPT) | ||

| Flow capacities | 3.5 m3/min (124 SCFM) | 3.2 m3/min (113 SCFM) | 4.0 m3/min (141 SCFM) | 3.6 m3/min (127 SCFM) |

| Particle removal down to | 40 micron(μ) | 5 micron(μ) | 40 micron(μ) | 5 micron(μ) |

| Operating Pressure | 1.3~13 kg/cm2 (20~185 PSIG) | |||

| Ambient Temperature | 2°c~60°c | |||

| Liquid Outlet | 3/8" PT (NPT) Auto Drain | |||

|

Dimensions |

Diameter 95 m/m ( 33/4 ") Length 235 m/m ( 91/4 ") | |||

|

Weight |

1.4 Kg (3.1 lbs) | |||

- Operating Pressure Drop: 0.1~0.7 kg/cm² (1.5~10 PSIG)

- Water collecting bowl is made of NYLON or Aluminum alloy.

The Best Combination

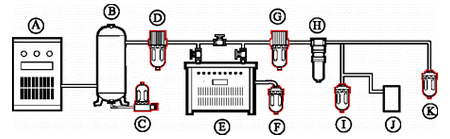

TONAIR compressed air separation filter is an accessory disposed in the middle section of the pipeline to filter the water and dirt in the compressed air pipeline, and it can be collocated with TONAIR AD-24 series compressed air automatic drain valve to eliminate the massive water and dirt in the storage tank at the front section, and combined with the AD-34 pipe end automatic drain valve to eliminate the water accumulated in the rear section of the pipe. This three-in-one quality product can completely remove the water and dirt in the compressed air product to save the cost of additional accessories and their maintenance fees, and additionally maintaining the smoothness of automated mechanical equipment operation as well as to extend their life span.

| No. | |

|---|---|

| A | Air Compressor |

| B | Receiver |

| C | TONAIR AD-24 Auto Drain Valve |

| D | TONAIR AF-104A Separation Filter |

| E | Air Dryer |

| F, I, K | TONAIR AD-34 Auto Drain Valve |

| G | TONAIR AF-104B Separation Filter |

| H | Oil Removal Filter |

| J | Pneumatic Machine or Tool |

English

English